Injection molding an IC into a connector or consumable item

InjectionmoldinganICintoa connectororconsumableitem

本文引用地址://m.amcfsurvey.com/article/169232.htmInjectionmoldingis the method of choice to embed integrated circuits (ICs) in medical sensorsandconsumables. This application note discusses the special care required when selecting the plastic material. It explains that the processing temperature must be low enough not to soften or liquefy the solder that attaches theICto a substrate. The article also discusses various plastic materialsand shows how they are not all equally suited for the sterilization required by medical applications. Only few of the sterilization methods are compatible to both the plastic material and ICs. An example of an IC embeddedintoaconsumableitemis shown.

Introduction

Integrated circuits (ICs) have been embedded in medical sensors and consumables or cables for quite some time. The concept and benefits of this technique are well understood.1However, very few companies have acquired the expertise for both the manufacturing process and selecting suitable plastics for the application. This document describes the injectionmoldingprocess in general, explains the critical temperatures, and gives an introduction to identifying suitable plastic materials.

What is injection molding?

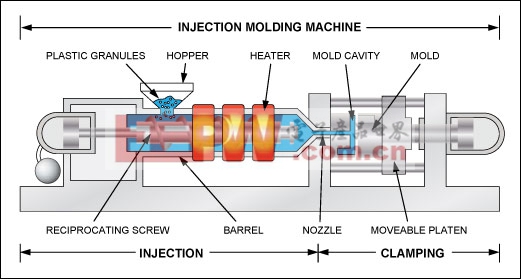

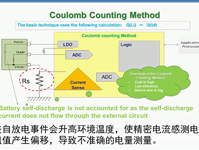

Injectionmolding is a process that forces molten plastic through a nozzleintoa mold cavity. The mold cavity can initially be empty or contain an object to be encased by the plastic.Figure 1shows a simplified drawing of an injection molding machine.2The plastic is fed into the machine as granules. A screw-type plunger transports the granules through a heated barrel towards the nozzle. Along the barrel there are typically three heating zones called rear, center, and front. The front zone, next to the nozzle, is the hottest. On the way to the nozzle the plastic granules soften and become a homogenous mass, which is forced under high pressure into the mold cavity, where it quickly cools and hardens. The mold is then opened to remove the molded object and to prepare the mold for the next cycle. Theprocessing conditionsspecification in the data sheet for the plastic material lists the appropriate temperatures of the zones and the mold.

Figure 1. The principle of an injection molding machine.

The critical temperature

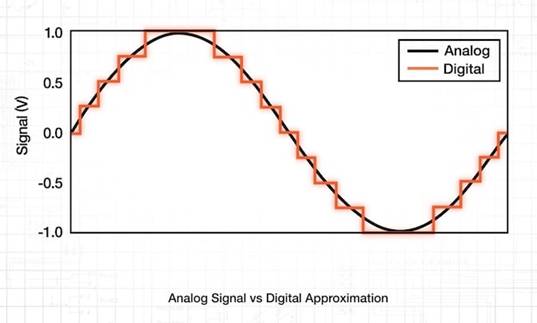

Besides pressure and filling speed, temperature is a critical parameter in the injection molding process. Temperature is also critical for the object to be encased. An IC by itself can handle up to 300°C for a short time without any harm. This temperature is permissible if the IC to be encased is wired-bonded to a substrate (circuit board) or if it is a plastic-packaged IC with crimped-on pins or in an SFN package3with exposed contact areas. However, if the IC is soldered to a circuit board, the critical temperature for injection molding depends on whether the IC assembly is lead (Pb)-free or not. Lead-free ICs (plastic packaged or bumped die, also known as flip chip, UCSP, or WLP) require lead-free solder, which has a melting temperature of approximately 217°C. Traditional plastic-packaged ICs and RoHS-compliant bumped dies require standard solder (Sn/Pb 63/37), which has a melting temperature of approximately 183°C. The melting temperature must not be confused with the reflow oven temperature setting, which is 235°C for lead-free and 215°C for standard products.

Finding the right plastic

With roughly 30,000 different materials available for injection molding,4finding the right plastic may appear like a serious challenge. The task becomes easier with some insight into the characteristics of various plastic materials.5

There are thermosetting plastics, which can be heated and run through an injection molding machine just once. Epoxy, a plastic commonly used for IC packages, falls into this category. Once processed, the thermosetting plastic remains solid, regardless of the temperature. There are thermoplastics, which soften whenever they are heated. Thermoplastics can have an amorphous or semi-crystalline structure, which affects mechanical stability, chemical/wear resistance6, 7and suitability to sterilization methods.Table 1shows a selection of plastic materials for injection molding.

Table 1. Typical plastics for injection molding

| Name | Full Name | Cost | Structure | Front Zone Temp. (°C) | Mold Tem perature (°C) | Sterilization Compatibility7, 8, 9, 10 |

| ABS | Acrylonitrile butadiene styrene | Low | Amorphous | 210 to 232 | 63 to 85 49 to 85 |

ETO CD RAD |

| HDPE | High-density polyethylene | Low | Semi-crystalline | 199 to 227 171 to 199 |

21 to 66 21 to 52 |

ETO CD (rad) |

| LDPE | Low-density polyethylene | Low | Semi-crystalline | 199 to 227 | 21 to 66 | ETO CD (rad) |

| PA | Nylon 6/6 | Medium | Semi-crystalline | 282 to 293 249 to 271 |

66 to 107 | AUT ETO CD VHP |

| PBT | Polybutylene terephthalate | Medium | Semi-crystalline | 243 to 257 216 to 232 |

66 to 121 | AUT ETO RAD |

| PC | Polycarbonate | Medium | Amorphous | 293 to 310 216 to 232 |

82 to 121 66 to 121 |

AUT ETO (rad) |

| PET | Polyethylene terephthalate | Medium | Semi-crystalline | 238 to 260 | 135 to 163 | AUT ETO RAD |

| PMMA | Acrylic | Low | Amorphous | 188 to 210 221 to 238 |

79 to 107 38 to 66 |

ETO CD VHP |

| POM | Acetal | Medium | Semi-crystalline | 188 to 210 177 to 199 |

82 to 121 | AUT ETO |

| PP | Polypropylene | Low | Semi-crystalline | 204 to 227 177 to 193 |

32 to 66 | AUT ETO CD VHP |

| PS | Polystyrene | Low | Amorphous | 221 to 238 204 to 221 |

38 to 66 | ETO CD VHP RAD |

| SAN | Styrene acrylonitrile | Low | Amorphous | 243 to 260 210 to 232 |

52 to 82 38 to 79 |

― |

Legend:

AUT: material is well suited for autoclave sterilization.

ET material is well suited for etylene oxide sterilization.

CD: material is well suited for chlorine dioxide sterilization.

VHP: material is well suited for vaporized hydrogen peroxide sterilization.

RAD: material is well suited for gamma ray or electron beam sterilization.

(rad): material may change its characteristics, e.g., discolor, when exposed to gamma rays or electron beams.

评论