车载冰箱单极驱动实现稳定温度

根据电流方向,Peltier设备可以实现加热和制冷。

多数工程师都知道电晶体冰箱被称为Peltier设备,或更普通的TECs(热电冷却器),也知道怎样对温度敏感的电子器件有效制冷,例如光学探测器和电晶体激光器。也许缺少认同,但也是共识,TECs为双向热泵,根据供电电流的方向,可以进行加热和制冷。TECs因此被作为精确微型调温装置的基础,维持温度在设定范围之间,避免周围温度的漂移。

双向TEC驱动存在不便于设计的问题。它需要双重两极电源供电或相对复杂的H桥驱动输出电路,包括一系列电源晶体管在热流指示所需的方向上,选择性的反转TEC激励。但另一个方法提供用消耗效率来简化问题的优势。本设计方案提出一个独特的方法实现双向TEC温度控制,避免双电源供电的不便和双向驱动的复杂。它采用所有TECs很少人知道的词:驱动电流异常高水平下的网络热流内在反转。

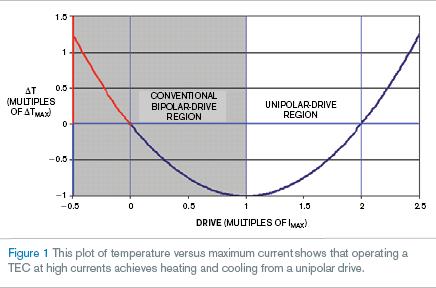

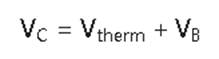

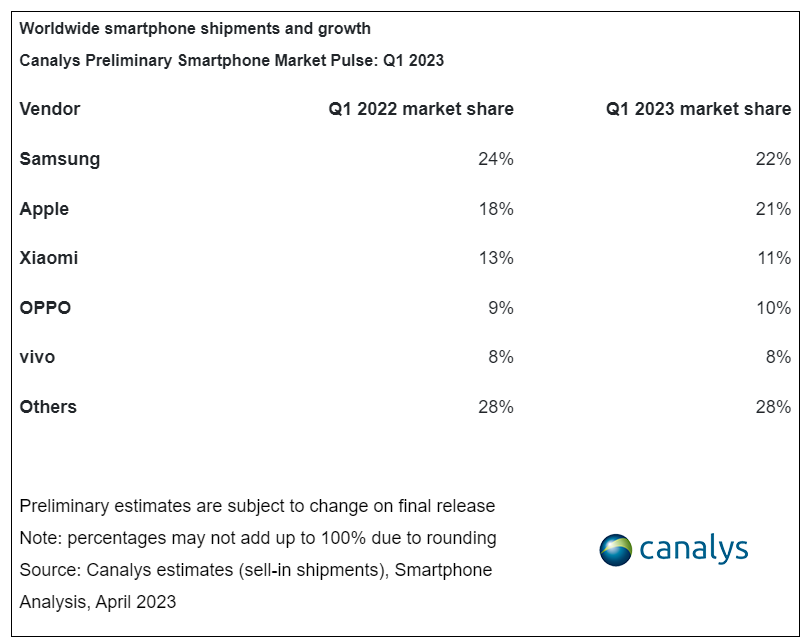

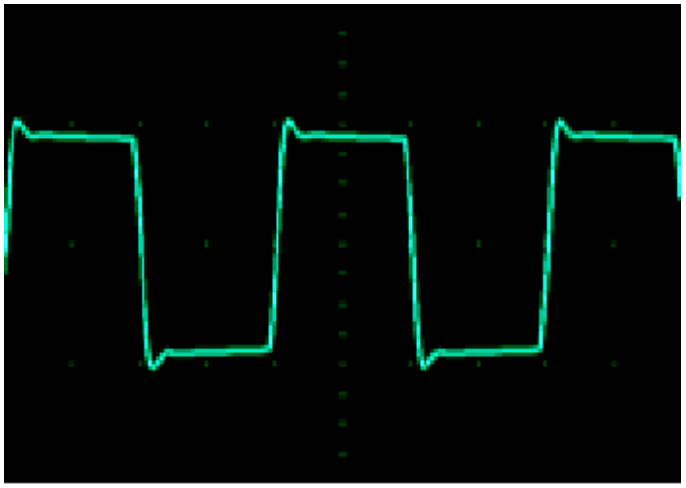

每个TEC(包括IMAX)的性能驱动电流,导致最大网络冷却。绘出热转递随相对IMAX的驱动电流,形成一条典型的抛物线曲线(图1)。左边图中灰色的半边显示常用双极TEC的工作区域,将驱动电流划分出–0.5×IMAX

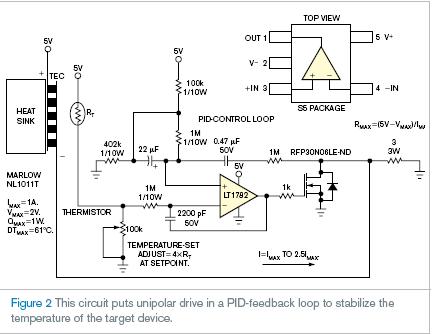

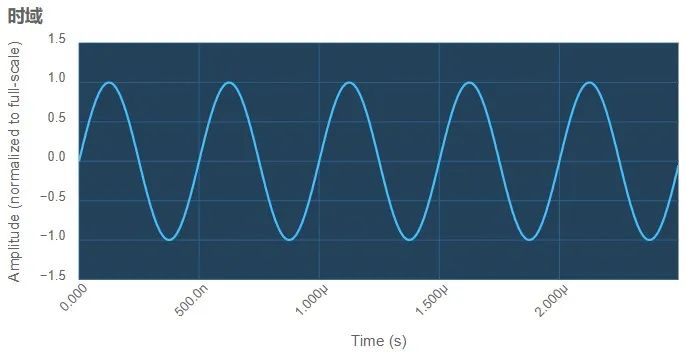

图2显示了高性能PID(比例-积分-微分)反馈环的执行情况。器件数少于双极驱动方案的1/4。反馈稳定性高,建立时间短。缺点是电流为常规双极驱动器的150%,限制了该技术应用于能量消耗和热耗散要求不严格和适当的小型TECs。

英文原文:

Thermoelectric-cooler unipolar drive achieves stable temperatures

Depending on the direction of current flow, Peltier devices can both heat and cool.

W Stephen Woodward, Chapel Hill, NC; Edited by Charles H Small and Fran Granville -- EDN, 12/3/2007

Most engineers know about the solid-state refrigerators called Peltier devices or, more commonly, TECs (thermoelectric coolers) and how they can actively cool temperature-sensitive electronic components, such as optical detectors and solid-state lasers. It’s also common knowledge—although perhaps less so—that TECs are bidirectional heat pumps and can therefore both heat and cool, depending on the direction of the supplied drive current. TECs can therefore serve as the basis for precision microthermostats, maintaining a predetermined temperature against ambient-temperature excursions that range both above and below the setpoint.

The rub is that bidirectional-TEC drive tends to be an inconvenient design problem. It requires either dual bipolar power supplies or relatively complex H-bridge-drive output circuits involving arrays of power transistors that selectively reverse the TEC excitation as the required direction of heat flow dictates. But an alternative method offers advantages whenever si mplicity matters more than efficiency. This Design Idea presents a novel approach to bidirectional-TEC-temperature control that avoids both the inconvenience of dual power supplies and the complexity of bidirectional drive. It works by exploiting a little-known quirk of all TECs: the inherent reversal of net heat flow at unconventionally high levels of drive current.

The specifications of every TEC include IMAX, the drive current that results in maximum net cooling. Plotting heat transfer versus drive current relative to IMAX results in a typical parabolic curve (Figure 1). The left-hand, gray half of the plot in the figure shows the usual bipolar TEC’s operating region, which confines drive current to the range of –0.5×IMAX

Figure 2 shows an implementation of the concept in a high-performance PID (proportional-integral-derivative)-feedback loop. The component count is less than one-fourth that of a comparable bipolar-drive design. Feedback stability is robust, and settling time is short. The downside is a current draw as much as 150% higher than that for a conventional bipolar driver, which limits the technique to applications in which power consumption and heat dissipation aren’t critical priorities and small TECs are adequate.

评论